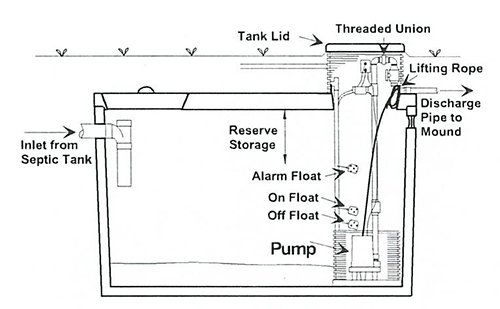

The pump chamber is a concrete, fiberglass or polyethylene container that collects the septic tank effluent. The chamber contains a pump, pump control floats, and a high water alarm float. The pump action may be controlled either by the use of control floats or by timer controls. Control floats are set to turn the pump “ON” and “OFF” at levels for pumping a specific volume of effluent per dose. Timer controls are set to produce both the length of the dose and the interval or rest period doses.

The high water alarm float sounds an alarm to warn you of any pump or system malfunction. If pump timer controls are used, the alarm also will warn you of excessive water use in the home. The float is set to start when the effluent in the pump chamber rises above the “ON” float. The alarm should consist of a buzzer and an easily visible light. It should be on an electrical circuit separate from the pump.

The pump discharge pipe should have a union and valve for easy removal of the pump. A piece of nylon rope or other noncorrosive material should be attached to the pump for taking the pump in and out of the chamber.